Bathtub Handle

This is a replacement knob/handle for a standard bathtub I made. Why? Because it was too hard for Emma to

create something amazing

This is a replacement knob/handle for a standard bathtub I made. Why? Because it was too hard for Emma to

Epoxy resin has become a versatile and indispensable material in various industries and DIY projects. Its unique properties make it

The headphone collection is starting to get out of hand. I’ve seen many nice stands out there, but it’s more

Remix of the Spaceman into one of my favorite childhood toys. This design was very tedious, but pretty easy because

Remix of the Spaceman of the infamous DJ duo! The helmets were a bit tricky to make because they had

Guys. We’re in the middle of a global pandemic here (Covid19). There is a shortage on toilet paper, PPE and

I love my kamado! I’ve been wanting to design a custom bbq table for it because the old table didn’t

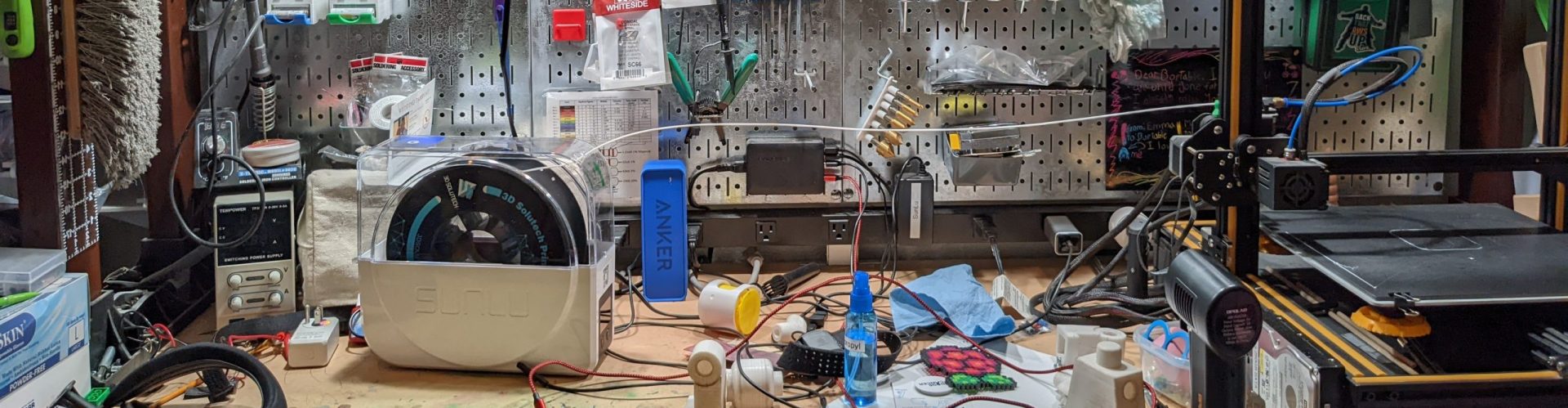

I created a little UV curation station/enclosure using a 405nm LED strip, MDF, and some clear PETG for some style!

I’ve been building my own CNC machine this year, and slowly designing parts to go with it. I needed a

There are many spool holders out there. The problem is there are many spool sizes that makes it hard to